Handheld Laser Welding Machine

Tsanangudzo pfupi yemukati chikamu

- Kune 6 welding modes uye akawanda welding nozzles kuti asangane akasiyana welding zvinodiwa; ine chengetedzo sensor function, iyo inoburitsa laser mushure mekubata simbi uye otomatiki inokiya mwenje kana yabviswa.

- Muchina uyu wakarongedzerwa otomatiki waya-feeder mudziyo, unogona kugadzirisa zviri nyore paramita uye kupa akawanda sarudzo dze.

vatengi.

- Kune 6 welding modes uye akawanda welding nozzles kuti asangane akasiyana welding zvinodiwa; ine chengetedzo sensor function, iyo inoburitsa laser mushure mekubata simbi uye otomatiki inokiya mwenje kana yabviswa.

- Huviri tembiricha uye huviri kudzora, kutenderera kwemvura kutenderera, kunogona kukurumidza kutonhorera yemukati pombi mhango ye welding musoro, uku kutonhora laser.

Product Display

Technical parameter

| Condition | New | Core Components | Laser Source |

| Usage | Weld Metal | Max. Output Power | 2000W |

| Applicable Material | Metal | Cnc Kana Kwete | Ehe |

| Cooling Mode | Mvura Kutonhora | Kudzora Software | Ruida/Qilin |

| Pulse Width | 50-30000Hz | Laser Simba | 1000w/1500w/2000w |

| Huremu (Kg) | 300 Kg | Certification | Ce, Iso9001 |

| Core Components | Fiber Laser Source, Fiber, Bata Laser Welding Musoro | Key Kutengesa Points | High-Kururama |

| Function | Metal Chikamu Laser Welding | Fiber Length | ≥10m |

| Applicable Industries | Mahotera, Zvitoro zvembatya, Zvitoro zvekuvaka | Core Components | Laser Supply |

| Mode Of Operation | Pulsed | Mushure meWarranty Service | Online Support |

| Focal Spot Diameter | 50μm | Wavelength | 1080 ±3nm |

| Vhidhiyo Inobuda Kuongorora | Provided | Graphic Format Inotsigirwa | Ai, Plt, Dxf, Dwg, Dxp |

| Nzvimbo Yekwakabva | Jinan, Shandong Province | Warranty Time | 3 Makore |

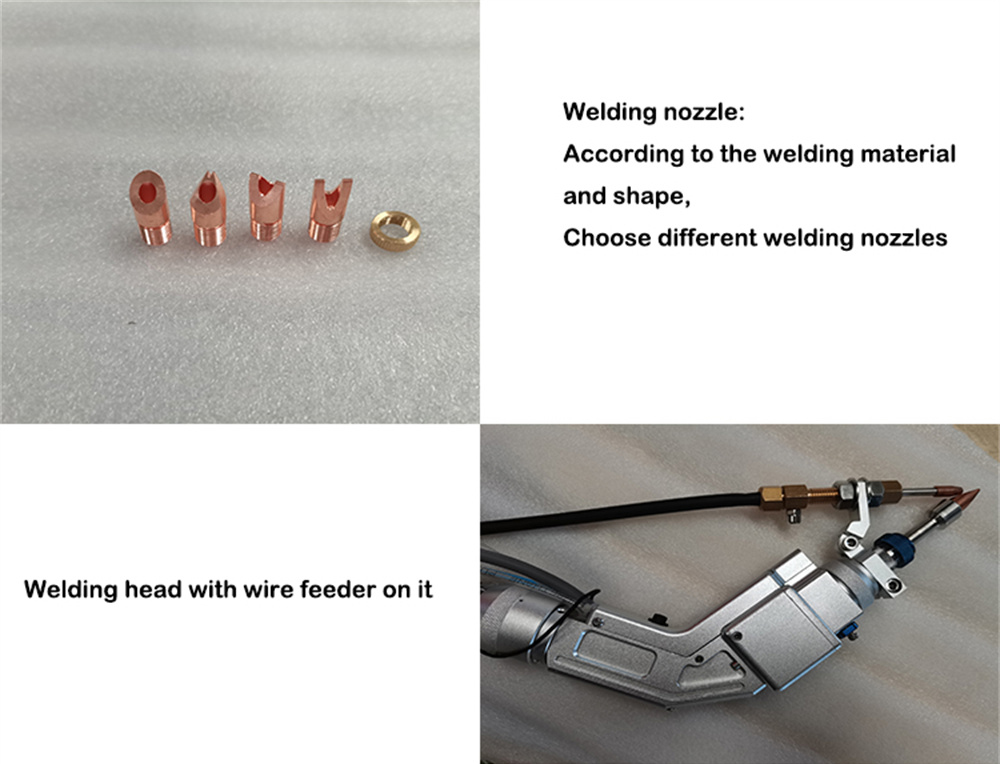

Zvikamu Zvikuru zveMuchina

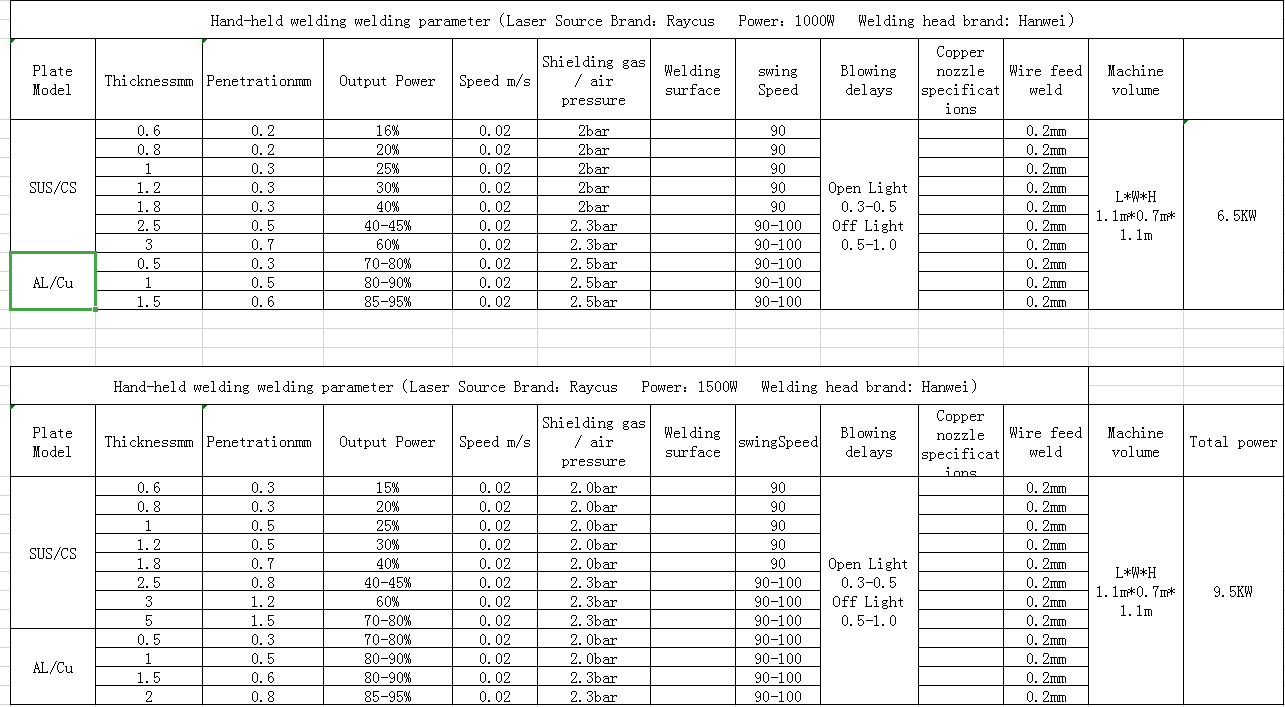

Welding parameter ye laser welding muchina

Configuration

| Laser Simba | 1000w | 1500W | 2000W | ||||||

| Welding Material | Simbi isina ngura | Carbon Steel | Aluminium | Simbi isina ngura | Carbon Steel | Aluminium | Simbi isina ngura | Carbon Steel | Aluminium |

| Welding Kukora (Mm) | 2 | 2 | 1 | 3 | 3 | 2 | 4 | 4 | 3 |

| Welding Kukora (Inch) |

|

|

|

|

|

|

|

|

|

| Adaptable Welding Wire | Welding Wire Diameter 0.8-1.6mm | ||||||||

| Weld Seam Chinodiwa | Filler Wire Welding≤1Mm Swinging Welding ≤15% YePlates Hukobvu≤0.3Mm | ||||||||

| Machine Weight | 220Kg | 220Kg | 300Kg | ||||||

| Saizi yemuchina(Mm) | 954X715X1080 | 954X715X1080 | 1155X715X1160 | ||||||

| Welding Gun Line Length | 10m (The Wire Feed Tube YeWaya Feeder Yakareba Mamita matatu) | ||||||||

| Welding Gun Weight | Vibrating Mirror Type (Qi Lin): 0.9Kg | ||||||||

| Machine Power | 7Kw | 9kw | 12Kw | ||||||

| Mutauro Unotsigirwa | Standard: Chinese, Chirungu, Korean, Vietnamese, Russian Japanese uye Spanish Inogona Kugadzirwa | ||||||||

| Voltage uye Frequency | Standard: 380V/50Hz Imwe Voltage uye Frequency Inosarudzwa | ||||||||

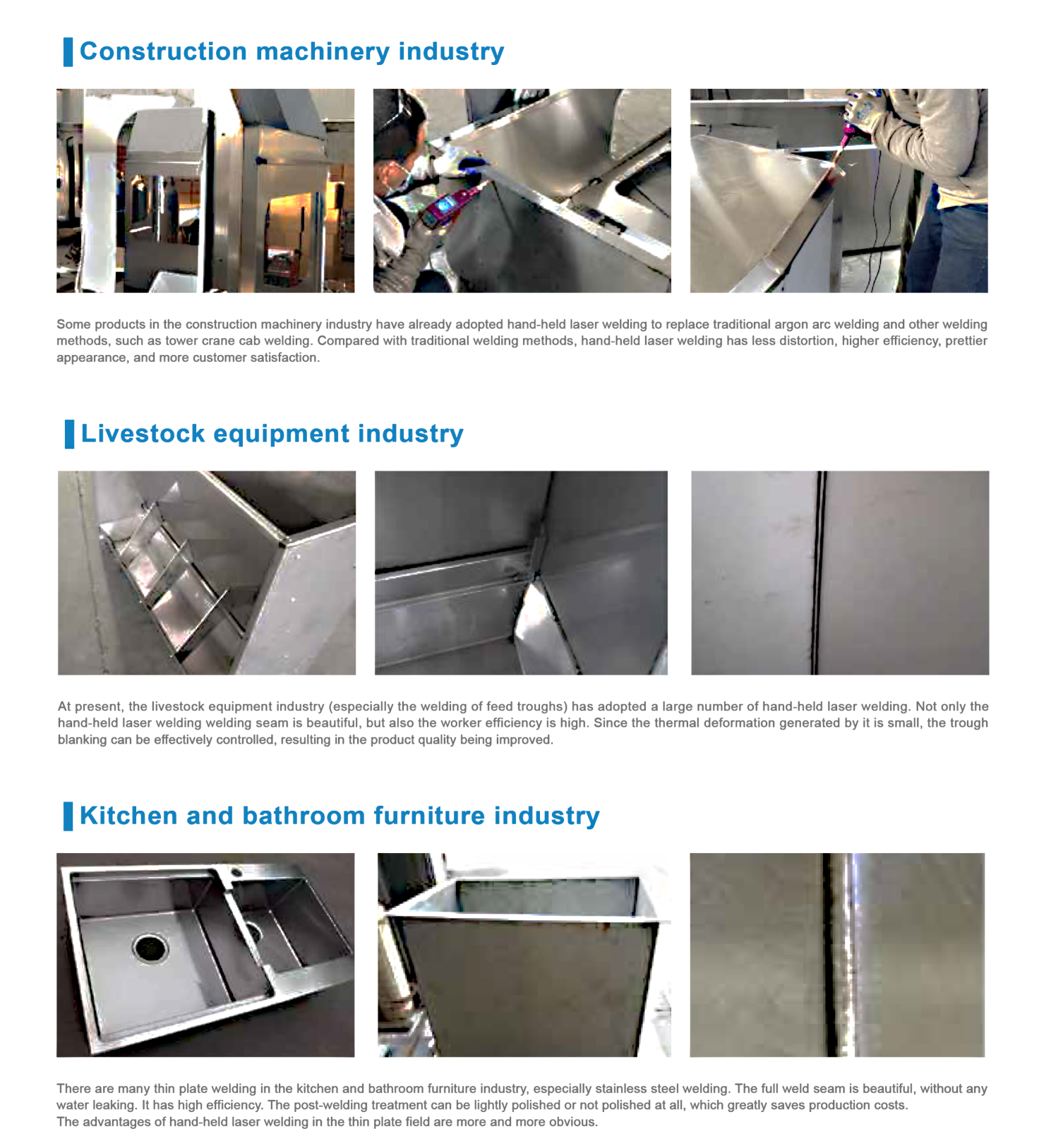

Indasitiri yekushandisa

Laser welding michina inoshandiswa zvakanyanya muindasitiri yekugezera: welding yemvura pombi majoini, kuderedza majoini, tees, mavharuvhu, uye mashawa. Indasitiri yegirazi: kukwenenzverwa kwesimbi isina simbi, titanium alloy uye zvimwe zvinhu pane buckle chinzvimbo, yekunze furemu uye zvimwe zvinzvimbo zvemagirazi. Indasitiri ye Hardware: impeller, kettle, mubato, nezvimwewo, welding yezvikamu zvakaoma zvekutsika uye zvikamu zvekukanda. Laser welding michina inoshandiswa zvakanyanya muindasitiri yemotokari: injini silinda gaskets, hydraulic tappet seal welding, spark plug welding, sefa welding, nezvimwe.

Advantage ye laser welding muchina

1. Wide welding range: Musoro unobatwa nemaoko welding unogadzirwa ne5m-10m yepakutanga optical fiber, iyo inokunda kuderedzwa kwenzvimbo yebasa rekushanda uye inogona kushandiswa kunze kwekunze uye kureba kureba;

2. Yakanaka uye inoshanduka kushandisa: Ruoko rwakabatwa nelaser welding yakashongedzerwa nemapulleys anofamba, ayo akasununguka kubata, uye anogona kugadziriswa chero nguva, pasina kudiwa kwezviteshi zvakagadziriswa, zvakasununguka uye zvinogadziriswa, uye zvakakodzera kune zvakasiyana-siyana zvekushanda mamiriro ezvinhu.

3. Nzira dzakasiyana-siyana dzekugadzira: kusungirirwa pane chero kona kunogona kuitika: stitch welding, butt welding, vertical welding, flat fillet welding, inner fillet welding, yekunze fillet welding, nezvimwewo. Welding pane chero kona inogona kuwanikwa. Mukuwedzera, anogonawo kupedzisa kucheka, kuputika uye kucheka kunogona kuchinjwa zvakasununguka, kungoshandura mhepo yemhangura yemhangura kune yekucheka mhangura yemhangura, iyo yakanyatsonaka.

4. Yakanaka welding mhedzisiro: ruoko-yakabata laser welding inopisa fusion welding. Kuenzaniswa neyechinyakare welding, laser welding ine yakakwira simba density uye inogona kuwana zvirinani welding maitiro. Tsvaira matambudziko, kudzika kukuru kwewelding, kunyungudika kwakakwana, kwakasimba uye kwakavimbika, uye kusimba kweweld kunosvika kana kutopfuura iyo base simbi pachayo, isingagone kuvimbiswa nemichina yakajairwa welding.

5. Welding seam haidi kukwenenzverwa: Pashure pechinyakare welding, welding point inoda kukwenenzverwa kuti ive nechokwadi chekutsvedzerera uye kwete roughness. Iyo inobatwa nemaoko laser welding inongoratidza mamwe mabhenefiti mukugadzirisa mhedzisiro: kuenderera mberi welding, yakatsetseka isina zviyero zvehove, yakanaka isina mavanga, uye mashoma anotevera ekukuya.

6. Hapana zvinobatika pakugadzira welding: Mukuona kwevanhu vakawanda, kushanda kwewelding ndeye "goggles muruoko rworuboshwe uye welding wire muruoko rworudyi". Nekudaro, nemuchina wekubata laser welding muchina, iyo welding inogona kupedzwa nyore, uye mutengo wezvinhu mukugadzira uye kugadzirisa unodzikiswa.

7. Iine maalarms akawanda ekuchengetedza, iyo welding tip inoshanda chete kana shanduko inobata kana inobata simbi, uye chiedza chinongovharwa mushure mokunge workpiece yabviswa, uye kushandura kunobata kune sensor yekushisa kwemuviri. Kuchengetedzwa kwepamusoro, kuve nechokwadi chekuchengetedzwa kwevashandi panguva yebasa.

8. Chengetedza mutengo webasa: Kuenzaniswa nearc welding, mutengo wekugadzirisa unogona kuderedzwa ne30%. Iko kushanda kuri nyore uye kuri nyore kudzidza uye nekukurumidza kudzidza, uye hunyanzvi chikumbaridzo cheanoshanda hachina kukwirira. Vashandiwo zvavo vanogona kushandirwa mushure mekudzidziswa kwenguva pfupi, uye vanogona kuwana zviri nyore zvemhando yepamusoro-welding mhedzisiro.