Robhoti mhando Laser Welding Machine

Product Display

Technical parameter

| Six-Axis Robot | Tuling | Core Components | Laser Source |

| Usage | Weld Metal | Max. Output Power | 2000W |

| Applicable Material | Metal | Cnc Kana Kwete | Ehe |

| Cooling Mode | Mvura Kutonhora | Magetsi Uye Pneumatic Systems | Schneider |

| Wavelength | 1090Nm | Laser Simba | 1000w/1500w/2000w |

| Huremu (Kg) | 600 Kg | Certification | Ce, Iso9001 |

| Core Components | Fiber Laser Source, Fiber, Bata Laser Welding Musoro | Key Kutengesa Points | High-Kururama |

| Function | Metal Chikamu Laser Welding | Fiber Length | ≥10m |

| Applicable Industries | Mahotera, Zvitoro zvembatya, Zvitoro zvekuvaka | Core Components | Laser Source |

| Mode Of Operation | Pulsed | Mushure meWarranty Service | Online Support |

| Focal Spot Diameter | 50μm | Maximum Coverage | 1730mm |

| Vhidhiyo Inobuda Kuongorora | Provided | Graphic Format Inotsigirwa | Ai, Plt, Dxf, Dwg, Dxp |

| Nzvimbo Yekwakabva | Jinan, Shandong Province | Warranty Time | 3 Makore |

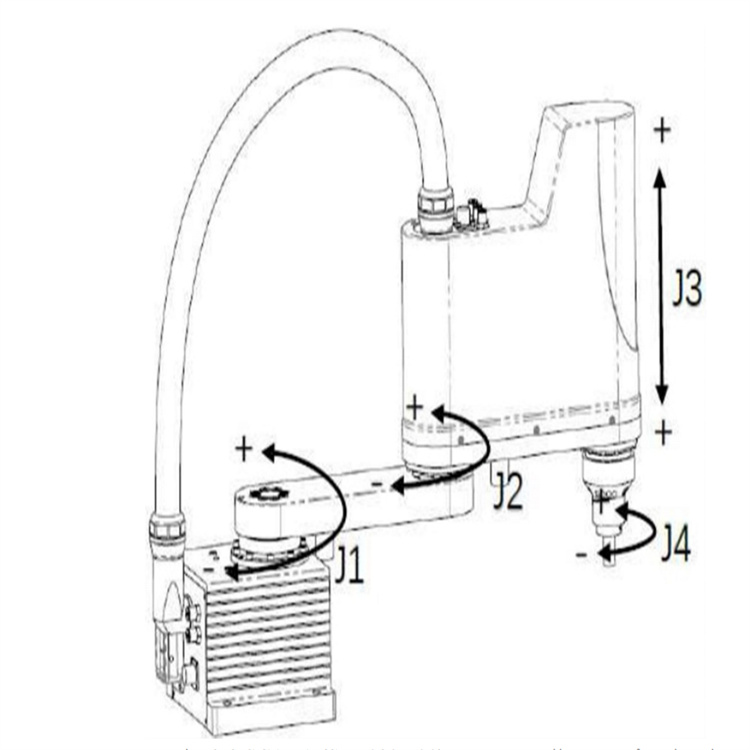

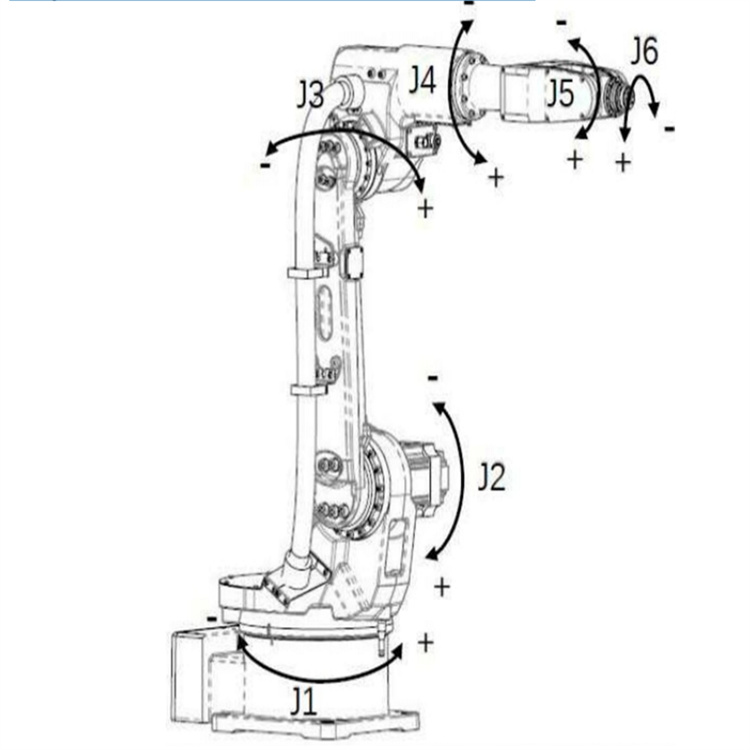

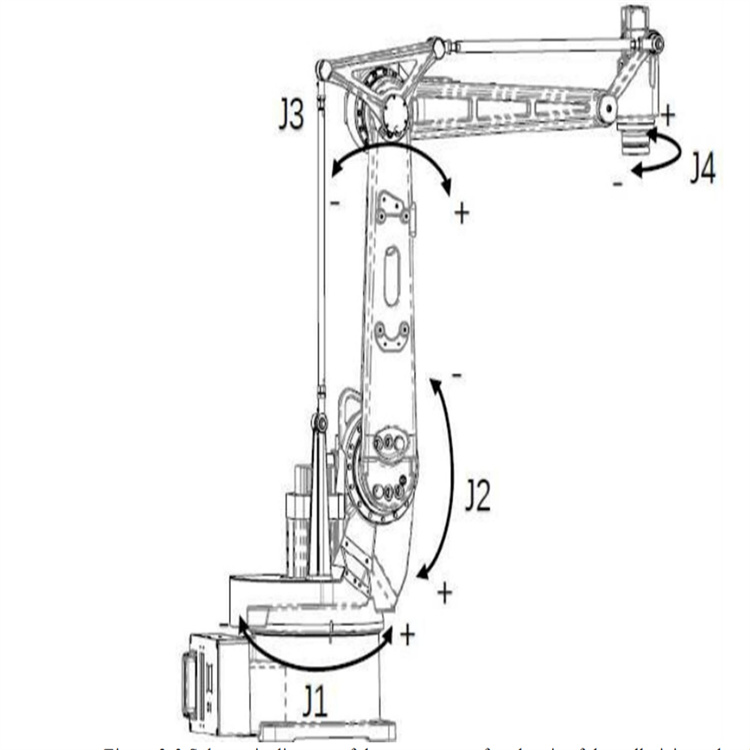

Robhoti ruoko

Iyo robhoti axis inogona kuve inotenderera axis kana yekushandura axis, uye maitiro ekushanda eiyo axis inotarwa neiyo mechanical chimiro. Iyo robhoti axis yakakamurwa kuita inofamba axis yerobhoti muviri uye yekunze axis. Iyo shaft yekunze yakakamurwa kuita tafura inotsvedza uye chinzvimbo. Kunze kwekunge zvatsanangurwa neimwe nzira, iro robhoti axis inoreva kufambisa axis yemuviri werobhoti.

Turing marobhoti akakamurwa kuva matatu marudzi emaindasitiri marobhoti:

Indasitiri matanhatu-axis robhoti: inosanganisira matanhatu ekutenderera matemo

SCARA: ine matemo matatu ekutenderera uye imwe shanduro axis

Palletizing manipulator: kusanganisira mana anotenderera shafts The joint motion of robot inoratidzwa mumufananidzo.

Kushandiswa kweRobhoti welding muchina

1.Machinery Manufacturing Field

Nekuwedzerwa kwemabasa ekuwelda muindasitiri yekugadzira michina, iyo welding ine mamiriro ekushanda asina kunaka uye nemwaranzi yakakura yekupisa, rinova basa rine njodzi. Kune zvakare akawanda mahombe emidziyo mukugadzira michina, izvo zvinowedzerawo kuoma kwewelding. , Welding robhoti ndeye otomatiki mechini midziyo inobata basa rewelding, iyo inosunungura kusimba kwevashandi uye inobatsira kuvandudza mwero weautomation mumunda wekugadzira michina.

2.Automobile uye auto zvikamu:

Mumakore achangopfuura, kuitira kuzadzisa zvinodiwa neveruzhinji, indasitiri yemotokari yakaratidza kusimukira kwakasiyana. Welding yechinyakare haigone kusangana nepamusoro welding zvinodiwa zvekugadzira mota uye auto zvikamu. , The welding seam yakanaka uye yakasimba. Mumashopu mazhinji emazuva ano ekugadzira mota, mitsetse yekubatanidza marobhoti yakaumbwa.

3.Mudziyo wemagetsi:

Munda wemidziyo yemagetsi ine zvakati wandei zvinodiwa zvemhando yewelding. Nekuwedzera kuri kuita kudiwa kwemidziyo yemagetsi munharaunda, zvemagetsi zviri kutarisana nematambudziko makukutu uku zvichikura nekukurumidza. Welding marobhoti anogona kudzikamisa welding mhando uku uchiona kugadzirwa kwakanaka. Iyo chaiyo welding yemidziyo yakakwira katatu kana kana kupfuura iyo yebasa remaoko.

4. Muchadenga:

Mukugadzirwa kwendege, kune zvingangoita chiuru zvemuviri welding, uye zvikamu zvinoda kusvika gumi zvinobatanidzwa. Zvizhinji zvezvinhu zvakakosha zvinotakura zvinotakura zvendege zvinoshandisa zvikamu zvakasungwa. Muviri wendege uri pasi pekumanikidzwa kukuru panguva yekubhururuka, saka welding Izvo zvinodikanwa zvakaomesesa, uye robhoti yewelding inogona kuchinjika kuseta iyo welding paramita kuburikidza neotomatiki welding seam yekutevera tekinoroji kuti inyatso kubatanidza chimiro chendege.

Kugadziriswa kwemuchina

- Wire feeding mechanism. Kusanganisira kana chinhambwe chekudyisa waya chiri chenguva dzose, kana mukoto wekudyisa waya wakuvadzwa, uye kana paine alarm isina kujairika; Kunyangwe kuyerera kwegesi kwakajairika; Kunyangwe iyo welding torch kuchengetedza system yakajairika. (Hazvibvumidzwe kuvhara mwenje wewelding webasa rekuchengetedza kuchengetedza);Kunyangwe iyo mvura inotenderera system iri kushanda zvakajairwa;Edza TCP (inokurudzirwa kuunganidza chirongwa chekuyedza nekuimhanyisa mushure mekuchinja kwega kwega)

2. Kuongorora kwevhiki nevhiki nekugadzirisa

1. Geza imwe neimwe akisi yerobhoti; Tarisa chokwadi cheTCP; Tarisa huwandu hwemafuta asara. ;Tarisa kana zero chinzvimbo cheakisi yega yega yerobhoti yakarurama; Chenesa sefa kuseri kwetangi remvura yemuchina wewelding.; Geza sefa painopinzwa mhepo yakamanikidzwa; Chenesa tsvina pamuromo wetochi remoto kudzivirira kuvhara kutenderera kwemvura; Chenesa nzira yekudyisa waya, kusanganisira vhiri rekudyisa waya, vhiri rekutsikirira waya uye chubhu yekutungamira waya; Tarisa uone kana hose hose nehose yewaya hosi zvakuvadzwa kana kutyoka. (Zvinokurudzirwa kubvisa hose hose yese uye kuichenesa nemhepo yakamanikidzwa); Tarisa uone kana iyo welding torch kuchengetedza system yakajairika uye kana bhatani rekunze rekumisa emergency rakajairika.