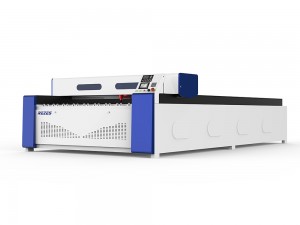

Matatu mune Imwe Laser Welding Machine

Product Display

Technical parameter

| Application | Laser Welding Kucheka uye Kuchenesa | Applicable Material | Metal zvinhu |

| Laser Source Brand | Raycus/MAX/BWT | CNC kana Kwete | Ehe |

| Pulse Width | 50-30000Hz | Focal Spot Diameter | 50μm |

| Output Power | 1500W/2000W/3000W | Kudzora Software | Ruida/Qilin |

| Fiber Length | ≥10m | Wavelength | 1080 ±3nm |

| Certification | CE, ISO9001 | Kutonhodza system | Kutonhora kwemvura |

| Mode of Operation | Continuous | Feature | Kuchengetedza kwakaderera |

| Machinery Test Report | Provided | Vhidhiyo inobuda yekuongorora | Provided |

| Nzvimbo Yekwakabva | Jinan, Shandong Province | Warranty nguva | 3 years |

Machine Vhidhiyo

Hunhu hweVatatu mune Imwe Laser Welding Machine

1. High simba density uye yakakwirira welding simba

Iyo laser beam simba density yemuchina unoenderera mberi wefiber laser welding wakakwira zvakanyanya, unogona kukurumidza kunyungudutsa simbi zvinhu uye kugadzira weld yakasimba. Iko kusimba kwemagetsi kunogona kuenzana kana kutokwira kupfuura iyo yezvinhu zvevabereki.

2. Mawelds akanaka, hapana post-processing inodiwa

Iyo welds inogadzirwa nelaser welding yakatsetseka uye yakafanana, isina kuwedzera kukuya kana kupukuta, izvo zvinoderedza zvakanyanya mutengo wepost-processing. Inonyanya kukodzera maindasitiri ane zvakakwirira zvinodiwa pakuonekwa kwewelding, senge zvigadzirwa zvesimbi isina tsvina, indasitiri yekushongedza simbi, nezvimwe.

3. Fast welding speed uye yakagadziridzwa kugadzirwa zvakanaka

Kuenzaniswa nemaitiro echinyakare ekugadzira machira (akadai seTIG/MIG welding), kumhanya kweinoenderera mberi fiber laser welding michina inogona kuwedzerwa ne2-10 nguva, ichivandudza zvakanyanya kushanda kwekugadzira, uye inokodzera kugadzirwa kwehuwandu.

4. Diki rinopisa rinopisa nzvimbo uye diki deformation

Nekuda kweiyo yekutarisisa hunhu hwelaser, iyo yekupisa yekuisa munzvimbo yewelding idiki, ichideredza deformation yekupisa kweiyo workpiece, kunyanya inokodzera welding chaiyo zvikamu, senge zvigadzirwa zvemagetsi, zvigadzirwa zvekurapa, nezvimwe.

5. Inogona weld zvakasiyana-siyana zvesimbi zvinhu, nehupamhi hwekushandisa

Inoshanda kune Stainless simbi, kabhoni simbi, aruminiyamu alloy, mhangura, nickel alloy, titanium alloy uye mamwe simbi uye alloys adzo, anoshandiswa zvakanyanya mukugadzira mota, sheet metal processing, aerospace, midziyo yemagetsi, midziyo yekurapa uye mamwe maindasitiri.

6. High degree of automation, inogona kubatanidzwa ne robot welding

Inoenderera mberi fiber laser welding muchina unogona kubatanidzwa nemarobhoti uye CNC masisitimu kuti uwane otomatiki welding, kuvandudza mwero wehungwaru kugadzira, kuderedza kupindira kwemanyorero, nekuvandudza kugadzirwa kunoenderana uye kugadzikana.

7. Kushanda kuri nyore uye mari yekuchengetedza yakaderera

Iyo midziyo inotora indasitiri yekubata interface, inogadziriswa paramita, uye nyore kushanda; iyo fiber laser ine hupenyu hurefu (kazhinji inosvika 100,000 maawa) uye yakaderera mutengo wekugadzirisa, iyo inoderedza zvakanyanya mutengo wekushandisa kumabhizinesi.

8. Tsigira handheld uye automated modes

Iwe unogona kusarudza handheld welding musoro kuti uwane flexible welding, iyo yakakodzera kune yakakura kana isina kujairika workpieces; inogona zvakare kushandiswa neatomatiki workbench kana robhoti kusangana nezvinodiwa zvekugadzira mutsara wekugadzira.

9. Yakasununguka uye yakachengeteka, hapana welding slag, hapana utsi uye guruva

Kuenzaniswa neyechinyakare welding, laser welding haiburitse hutsi hwakawanda, sparks, uye welding slag, iyo ine hushamwari nharaunda uye yakachengeteka, uye inosangana neazvino maindasitiri akasvibira ekugadzira zviyero.

Welding samples

Service

1.Customized services:

Isu tinopa yakagadziridzwa fiber laser welding michina, tsika yakagadzirwa uye inogadzirwa zvinoenderana nezvinodiwa nevatengi. Kunyangwe iri welding yemukati, mhando yemhando kana yekumhanyisa kumhanya, isu tinogona kugadzirisa nekuigadzirisa zvinoenderana nezvinodiwa nemutengi.

2.Pre-kutengesa kubvunza uye rubatsiro rwehunyanzvi:

Isu tine timu ine ruzivo rwemainjiniya vanogona kupa vatengi nehunyanzvi pre-kutengesa mazano uye rutsigiro rwehunyanzvi. Kungave kusarudzwa kwemidziyo, zano rekushandisa kana gwara rehunyanzvi, tinogona kupa rubatsiro rwekukurumidza uye runoshanda.

3.Kurumidza kupindura mushure mekutengesa

Ipa nekukurumidza mushure mekutengesa tekinoroji rutsigiro kugadzirisa matambudziko akasiyana anosangana nevatengi panguva yekushandiswa.

FAQ

Q: Ndezvipi zvinhu zvinogona kugadzirwa nelaser welding muchina?

A: Inoenderera mberi fiber laser welding muchina inokodzera zvakasiyana siyana zvesimbi, senge: Stainless simbi, kabhoni simbi, aluminium alloy, mhangura, nickel alloy, titanium alloy, galvanized sheet, nezvimwe.

Kune simbi dzinoratidzira zvakanyanya (semhangura, aluminium), zvinodikanwa kusarudza yakakodzera laser simba uye welding paramita kuti uwane yakanaka welding mhedzisiro.

Q: Ndeipi iyo yakanyanya kukwenenzvera ukobvu hwelaser welding?

A: The welding ukobvu zvinoenderana Laser simba.

Mubvunzo: Ko laser welding inoda kudzivirira gasi?

A: Hongu, kudzivirira gasi (argon, nitrogen kana gasi rakasanganiswa) rinowanzodiwa, uye mabasa ayo anosanganisira:

- Dzivirira oxidation panguva yewelding uye kunatsiridza weld mhando

- Deredza chizvarwa che weld porosity uye wedzera simba re welding

-Kurudzira yakanyungudutswa dziva kusimba uye ita kuti weld iite zvakanaka

Q: Ndeupi musiyano uripo pakati pehandheld laser welding muchina uye otomatiki laser welding muchina?

A: Handheld: Inokodzera kuchinjika kushanda, inogona weld zvimiro zvisina kujairika uye mahombe workpieces, akakodzera diki nepakati batch kugadzirwa.

Automation: Inokodzera hukuru-hukuru, yakamisikidzwa kugadzirwa, inogona kubatanidza robhoti maoko uye welding workstations kuvandudza kugadzirwa.

Mubvunzo: Ko deformation ichaitika panguva yekupisa laser?

A: Kuenzaniswa nemaitiro echinyakare ekugadzira, laser welding ine yakaderera kupisa yekuisa uye diki-inopisa-inokanganiswa nzvimbo, uye kazhinji haiburitse deformation iri pachena. Kune zvinhu zvakatetepa, ma parameter anogona kugadziridzwa kuderedza kupisa kupinza uye kuwedzera kuderedza deformation.

Mubvunzo: Hupenyu hwesevhisi hwemidziyo yakareba kwenguva yakareba sei?

A: Hupenyu hwedzidziso hwefiber laser hunogona kusvika "100,000 maawa", asi hupenyu chaihwo hunoenderana nekushandiswa kwezvakatipoteredza uye kugadzirisa. Kuchengeta kutonhora kwakanaka uye kugara uchichenesa optical components zvinogona kuwedzera hupenyu hwemidziyo.

Q: Ndedzipi nyaya dzinofanira kutariswa pakutenga muchina welaser welding?

A: - Simbisa inodiwa welding zvinhu uye ukobvu, uye sarudza rakakodzera simba

- Funga kana otomatiki welding inodiwa kuti uvandudze kugadzirwa kwakanaka

-Sarudza mugadziri akavimbika kuti ave nechokwadi chemhando yemidziyo uye mushure mekutengesa-basa

- Nzwisisa kana zvakakosha kutonhora kana kudzivirira masisitimu anodiwa